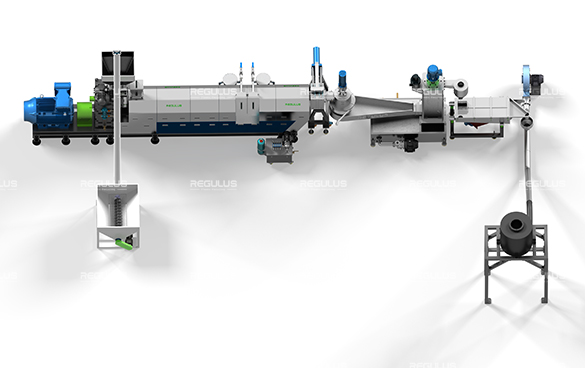

Single screw inoparara yekudzokorora muchina

Zvinyorwa

| Target Recycled Chinyorwa | HDPE, LDPE, PP, BOP, CPP, OPP, PA, PC, PS, PS, ABS | |||||

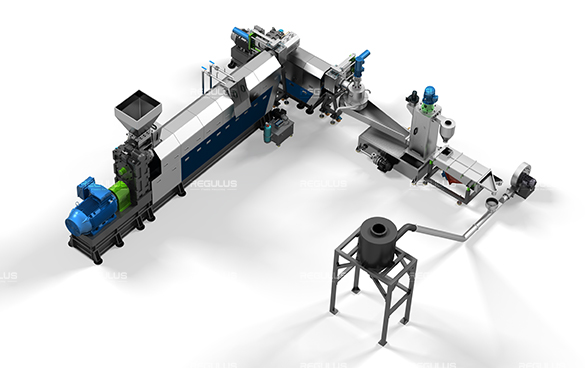

| Kuumbwa kwesystem | Screw Loader, single screw inopararira, kutanga kwekutanga, pelletizer, pelletizer | |||||

| Zvinhu zve screw | 38crmoal (Sacm-645), Bimetal (Inosarudzwa) | |||||

| L / d ye screw | 28/1, 30/1, 33/1, zvinoenderana nehunhu hwekudzokorodza) | |||||

| Heater yebhari | Ceramic heater kana kure-infrered heater | |||||

| Kutonhora kwebhari | Mweya kutonhora kwevateveri kuburikidza nevhu | |||||

| Pellasizing mhando | Mvura-mhete pellasizing / mvura-tambo pellasizing / pasi-mvura pelletizing | |||||

| Technical Services | Project Dhizaini, Kuvaka Kwefekitori, Kuisirwa uye Kurudziro, Commisketing | |||||

| Muchina Model | L / d | Single screw inoparara | ||||

| Screw diameter | EXTruder Motor | Kubuda Kunogona | ||||

| (mm) | (KW) | (KG / H) | ||||

| Xy100 | 100 | 33 | 75-90 | 200-300 | ||

| Xy120 | 120 | 33 | 90-110 | 250-400 | ||

| Xy130 | 130 | 33 | 132 | 450-550 | ||

| Xy160 | 160 | 33 | 160-200 | 550-850 | ||

| Xy180 | 180 | 33 | 220-250 | 800-1000 | ||

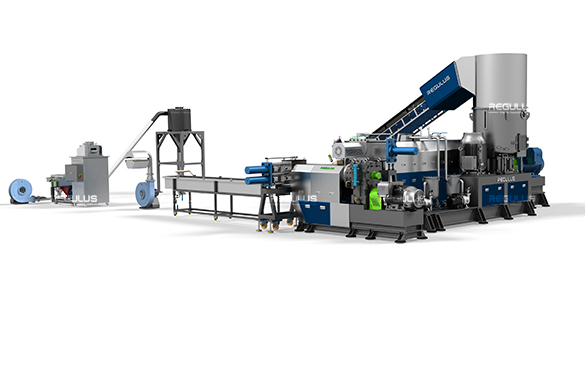

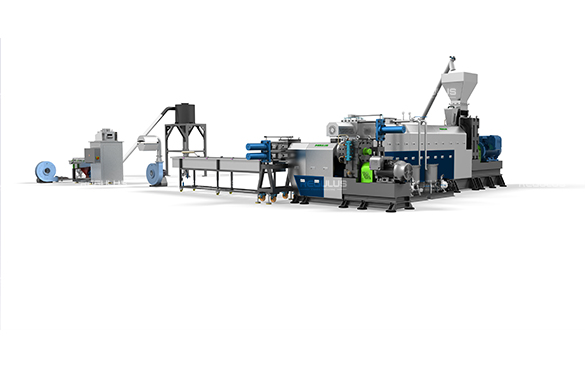

Double Stage Cutter Compactor Recycling pellasizing mutsara

Iyo nhevedzano imwe screw inowedzera uye pelletizing system inzvimbo yakakosha uye yakavimbika system, yakakodzera kudzoreredza uye kudzoreredza zvakare basa rezvematanda epurasitiki. Inosanganisa plasticzation uye pelletizing kune imwe nhanho uye yakakodzera kuti uongororwe zvidimbu kana maronda e-pe / pp / abs / hip / pc etc.

Zvigadzirwa zvekupedzisira zvinogadzirwa neyakagadzirwa screw Extrusion Line iri muchimiro chePellets / Granules, inogona kuiswa zvakananga mutsetse wefirimu

Spiral Feeding Machine

Mapundu kana kukora mapopoma mushure mekupwanyika, anoburitswa muzvikamu imwe chete. Zvichienderana neyakasiyana screw diamita yeimwe screw, iyo chaiyo kugona inogona kuvhara kubva ku100kg / h kusvika 1000kg / h, kuendesa mota simba: 2.2 kw. Kuburitsa pombi yakagadzirwa neStanless Steel zvinhu, Pipe Mukati Hukokara ndeye 2mm, pipe diameter ndeye 102mm.

Kudya Kwakakura (Volumetric)

Ichadyisa zvigadzirwa mumubati. Iko kurira kwekukurudzira kuti udzivise block yezvinhu pazasi peiyo Feeder. Kudyisa Hopper NeMureza Chiratidzo.

Kana iwe uchida kuumbiridza zvinhu, feads feaders ndeye sarudzo.

Single screw inoparara

Yedu yakasarudzika dhizaini imwe screw inowedzera zvinyoro-nyoro mapurasitiki uye homogeraiziisa zvinhu. Yedu bi-simbi yekubiwa ine yakakura anti-corrosion inopesana, kupfeka nguva inodzivirira uye refu hupenyu nguva.

Double Vacuum Degards nzvimbo

Nepamhepo mbiri dzisina kuderera.

Plate Type Screen Changer

Iyo ndiro yemhando yefaira yakagadzirwa mune inoenderera mberi mhando ine maviri mafirita mahwendefa. Iko kune imwe chete yefaira iri kushanda kana iyo skrini ichichinja.Rring-yakavezwa heater yekuchinja uye yakagadzikana kupisa

Hapana-STOP Piston Type Filter

1.a yenguva dzose-piston kaviri-station-station-station-streat kaviri plate / piston ina-station inogona kuiswa mumusoro wekutora kuendesa kuwanda kwekuita.

2.long screen hupenyu hwese, yakaderera skrini shanduko frequency: refu firita hupenyu nekuda kwenzvimbo huru dzepirita.

3. Easy ari nyore kushandisa uye hapana-stop mhando: nyore uye nekukurumidza skrini shanduko uye haufanire kumisa muchina unomhanya.

4.Very Low Operatment Mutengo.

Vertical mvura mhete granation system

1.WE-kugadzirisa pelletizoin musoro kune yakanakisa quolate quolity uye nguva refu kukwira kukonzeresa kuti vagare vasina mhosva.

2.

3.Easy uye nekukurumidza pelletizer blades changeallo, pasina basa rekugadzirisa rinoponesa nguva.

Yakatwasuka mvura mhete granulation system

1.WE-kugadzirisa pelletizoin musoro kune yakanakisa quolate quolity uye nguva refu kukwira kukonzeresa kuti vagare vasina mhosva.

2.

3.Easy uye nekukurumidza pelletizer blades changeallo, pasina basa rekugadzirisa rinoponesa nguva.

Vibration yakaoma

1.Vanonzi Dewatering vibration yekukwira kusanganisa pamwe chete nekaseni-mhando centrifugal dewatering parizvino masheya akanyanya kuomesa pellets uye kuderera simba rekushandisa.

2. Unganidza sieves: Iyo svive yakaiswa uye yakagadziriswa ne screws panzvimbo yeWalking, saka unogona kuchinja mbiru nyore mune ramangwana.

Vertical templele dehydrator

Kunyatsoshandiswa kusvibiswa kwemvura yepurasitiki yemvura mhete uye pasi pemvura kucheka zvimedu,

Vibrating skrini

Yaishandiswa kupatsanura saizi yemapurasitiki emapurasitiki