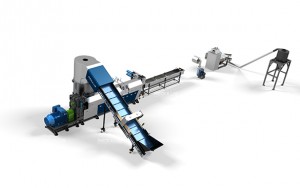

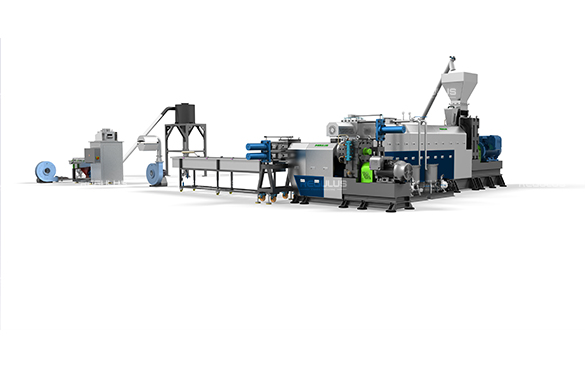

Single Stage Cutter Compactor Recycling pellasizing mutsara

Zvinyorwa

| Target Recycled Chinyorwa | HDPE, LDPE, PP, BOP, CPP, OPP, PA, PC, PS, PS, ABS | |||||

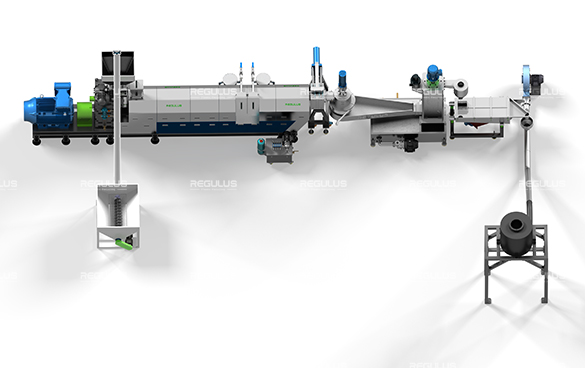

| Kuumbwa kwesystem | Bhandi rinonamira, kucheka concer, single screw inoparara, filtration,Pelletizer, Mvura inotonhorera mudziyo, chikamu chekushayiwa kwemvura, conveyor fan, chigadzirwa siro. | |||||

| Zvinhu zve screw | 38crmoal (Sacm-645), Bimetal (Inosarudzwa) | |||||

| L / d ye screw | 28/1, 30/1, 33/1, zvinoenderana nehunhu hwekudzokorodza) | |||||

| Heater yebhari | Ceramic heater kana kure-infrered heater | |||||

| Kutonhora kwebhari | Mweya kutonhora kwevateveri kuburikidza nevhu | |||||

| Pellasizing mhando | Mvura-mhete pellasizing / mvura-tambo pellasizing / pasi-mvura pelletizing | |||||

| Technical Services | Project Dhizaini, Kuvaka Kwefekitori, Kuisirwa uye Kurudziro, Commisketing | |||||

| Muchina Model | Compactor | L / d | Single screw inoparara | |||

| Vhoriyamu | Mota Simba | Screw diameter | EXTruder Motor | Kubuda Kunogona | ||

| (Liter) | (KW) | (mm) | (KW) | (KG / H) | ||

| XY-85 | 350 | 37 | 85 | 33 | 55 | 150-250 |

| XY-100 | 500 | 55 | 100 | 33 | 90 | 250-350 |

| XY-130 | 850 | 90 | 130 | 33 | 132 | 450-550 |

| XY-160 | 1100 | 110-132 | 160 | 33 | 185 | 650-800 |

| Xy-180 | 1500 | 185 | 180 | 33 | 250-280 | 900-1100 |

Cutter compactor epurasitiki kudzokorora pellasizing system

Iyo nhevedzano yekufananidza uye pellasizing system inosanganisa basa rekupwanya, kuenzanisa, kupuraseta uye poletizing nedanho rimwe. Inoshandiswa mumapurasitiki anodzokorora uye pellasizing maitiro. ACHSH TM System ndeyekudzikama uye kushanda kwakasimba kwePurasitiki firimu, raffias, mafaera, mabhegi, mabhegi ane midziyo yekudzora mari yemuchina wepamhepo. Inogona kupa yakakwira kubuda asi ine yakadzika simba rekupedza ption. Chikumbiro: PE, PP, PS, AB, XPS, EPS, PVB.

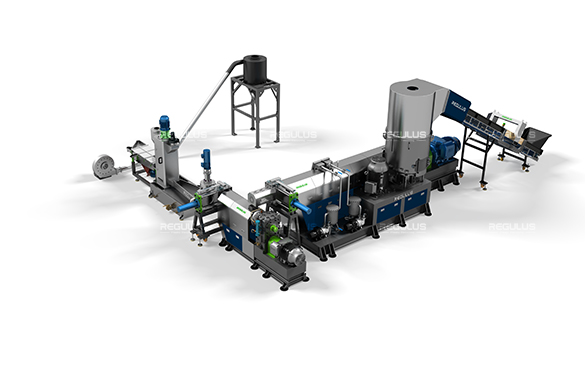

Kudya

Sekugadzira makajaho, matsime epurasitiki akadai sefirimu, kudzima, raffias yakaiswa mukamuri yekuenzanisa kuburikidza nebhandi conveyor; Kubata rolls 'scraPs, roll kuunza mudziyo sarudzo sarudzo yekudyira. Mota inotyaira yebhandi rebhandi uye kusunungura mudziyo unobatana neinverter. Kudyisa kumhanya kweBeltor Bhandi kana kurukurirano yekudzora ndeyekuti otomatiki zvichienderana nekuti yakazara sei iyo commender mukamuri yaCendel.

Kupwanya uye kuenzanisa

Compactor iri yakagadzirirwa nemhepo inonetesa mudziyo. Iine basa rekutenderera reRotor banga uye rator banga pazasi peConwlk, tembiricha yaCoconger uye kupusa uye guruva uye guruva pamusoro pezvinhu zvakashata zvichafamba pamusoro peConcal. Chishandiso ichi chinogona kuwana zvinobudirira zvinyoro uye guruva, izvo zvichadzivisa kushandisa imwe simba rekushandisa nekunyorova.This compactor inosanganisa pre-kupfuurira, kuderedzwa uye kuderedzwa kwekutsanya nekutsanya nekugadzikanakudyisa maitiro.

Iyo rotired blades of conffactor

Iyo inotenderera blade uye yakatemwa blade yakatemwa zvinhu kuita madiki madiki. Iyo yekupfekedza kupisa kunogadzirwa neyekumhanya-kumhanya inotenderera mabhureki kuchawedzera-kupisa uye kudzikira maruva.

Single screw inoparara

Yedu yakasarudzika dhizaini imwe screw inowedzera zvinyoro-nyoro mapurasitiki uye homogeraiziisa zvinhu. Yedu bi-simbi yekubiwa ine yakakura anti-corrosion inopesana, kupfeka nguva inodzivirira uye refu hupenyu nguva.

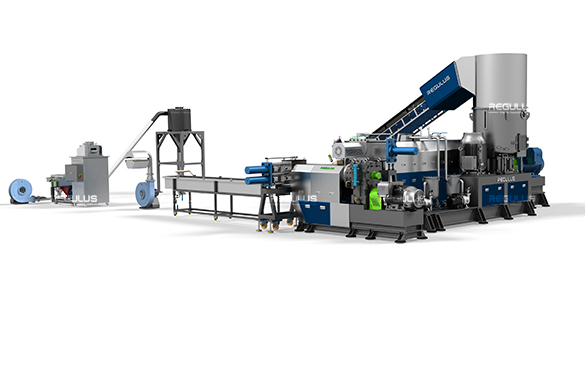

Double Vacuum Degards nzvimbo

Nepamhepo mbiri dzisina kuderera.

Plate Type Screen Changer

Iyo ndiro yemhando yefaira yakagadzirwa mune inoenderera mberi mhando ine maviri mafirita mahwendefa. Iko kune imwe chete yefaira iri kushanda kana iyo skrini ichichinja.Rring-yakavezwa heater yekuchinja uye yakagadzikana kupisa

Hapana-STOP Piston Type Filter

1.a yenguva dzose-piston kaviri-station-station-station-streat kaviri plate / piston ina-station inogona kuiswa mumusoro wekutora kuendesa kuwanda kwekuita.

2.long screen hupenyu hwese, yakaderera skrini shanduko frequency: refu firita hupenyu nekuda kwenzvimbo huru dzepirita.

3. Easy ari nyore kushandisa uye hapana-stop mhando: nyore uye nekukurumidza skrini shanduko uye haufanire kumisa muchina unomhanya.

4.Very Low Operatment Mutengo.

Strap Malld

Iyo Dhiza Dhiza Mol Inoshandiswa zvakanyanya, uye zvigadzirwa zvakaita sePP, Pe, Abs, Pet, Etc. inogona kuiswa ehupfumi uye hupfumi

Plastiki Granulation Line inotonhorera tangi

1.Vanonzi Dewatering vibration yekukwira kusanganisa pamwe chete nekaseni-mhando centrifugal dewatering parizvino masheya akanyanya kuomesa pellets uye kuderera simba rekushandisa.

2. Unganidza sieves: Iyo svive yakaiswa uye yakagadziriswa ne screws panzvimbo yeWalking, saka unogona kuchinja mbiru nyore mune ramangwana.

Plastiki Granulation Line inotonhorera fan system

Inoshandiswa kubvisa unyoro kubva kumapurasitiki mabrake

Plastiki Granulation Line Kucheka System

Inoshandiswa pakucheka mapurasitiki mitsetse mumapurasitiki

vibrating skrini

Yaishandiswa kupatsanura saizi yemapurasitiki emapurasitiki